|

|

Posted By RCI,

Tuesday, February 15, 2022

Updated: Wednesday, April 13, 2022

|

No pre-bottomer? No problem! With RCI Chocolate Boot Camp course taking place next week, we’re sharing a quick and easy solution, demonstrated by Instructor Joe Sofia with Cargill Cocoa & Chocolate, for candy makers who do not have a pre-bottomer on their enrober. This handy tip uses chocolate wafers as the pre-bottom for, in this case, moulded peanut butter meltaways. Joe explained, "When you pop the meltaways out of the mould, they are ready for the full enrobing since the wafer will adhere to the meltaway." Joe also added that it's important to apply the chocolate wafer while the center is still liquid so the two stick together. For this particular demonstration, a 22-millimeter silicon dome mould from Truffly Made was a perfect fit when using a standard chocolate wafer as the base. If you’re interested in more pro tips like this, consider attending RCI’s next Chocolate Boot Camp course in August 2022. If you’re not a member of RCI and you would like to be notified when registration opens, click here to be added to RCI’s email list. Crave more?Click here to subscribe and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices. Follow us on Facebook for even more sweet inspiration. Not a member? Click here to learn how RCI can help you build your sweet business.

Tags:

Bottomer

Chocolate

Chocolate Boot Camp

Enrobing

Pre-Bottomer

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, June 4, 2019

Updated: Monday, April 27, 2020

|

The most common way to make a meltaway is to combine tempered chocolate with melted coconut oil until it is smooth. Because coconut oil is a lauric fat, it must be added at a lower temperature so not to throw the chocolate out of temper. If the chocolate becomes untempered (or was never tempered to start with) the nice, smooth texture of the meltaway will eventually be replaced with an unpleasant mouthfeel due to the formation of fat globules.

Mixing Things Up

Consider this alternative method to making stable, smooth-textured meltaways with untempered chocolate. Instead of adding fat to tempered chocolate, combine untempered chocolate and coconut oil in a mixer. Mix at a slow speed until the temperature is below 78º F and has visibly thickened. Referred to as the “mixer method” in curriculum shared at RCI’s Chocolate Boot Camp®, it achieves the same desired stability and texture the meltaway is revered for, without the hassle of keeping temper.

If you live in the Connecticut area, it’s not too late to register for RCI’s Annual Convention & Industry Expo in Hartford, Connecticut June 3-7, 2019 at the Connecticut Convention Center. Attend RCI’s two-day Industry Expo for only $5 with promo code RCIHigh5. Click here to register online today!

As always, attending RCI’s Industry Expo is free to members! Extend your stay and we’ll extend the early-bird discount to offer you the best value! Register now and save $100 on the Convention Pass or 3-Day Pass when you use the promo code SAVE100.

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Tags:

Chocolate Boot Camp

Meltaways

Tempering

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, February 19, 2019

Updated: Monday, April 27, 2020

|

So, it’s February! And how are those New Year’s resolutions coming along?

Whether you made a resolution to improve your business this year or not, now is a great time to evaluate the goals you do have and measure your progress since setting those goals. Experts agree measuring your progress on an ongoing basis is a vital part of successfully attaining goals.

If you aspire to learn more about chocolate and expand your candy making skills, we’ve pulled sample questions from RCI’s Chocolate Boot Camp® “School of Knowledge” quiz, as a way to help you take a pulse of your chocolate knowledge.

1. Which of the following steps of cocoa bean processing must take place within the growing country?

A. Conching

B. Winnowing (shell removal)

C. Fermentation

D. All of the above

2. When tempering chocolate, what percentage of solid fat crystals is desired when process is complete?

A. 0.1 - 1.0%

B. 1.5 - 4.0%

C. 5.0 - 8.0%

3. Which of the following will contribute to bloomed bottoms?

A. Cold belt temperatures

B. Using chocolate in bottomer

C. High-viscosity chocolate

D. All of the above

4. When removing confections from freezer storage, typical temperature profile is:

A. 0°F - 30°F - 70°F

B. 0°F - 40°F - 70°F

C. 0°F - 50°F - 70°F

Now that you've completed the sample quiz, ask yourself, how confident do you feel in your answers? Would you qualify for master chocolatier status or could you use a refresher on the subject? See post #295 for the answers.

Warren Buffet once said, “The best investment you can make is an investment in yourself, the more you learn the more you’ll earn.” Whether you're a veteran chocolatier or a newcomer to the industry, if you aspire to learn more and expand your candy making skills, consider ways to invest in your education. Thankfully education is more accessible than ever before! Education is available in all different formats; print, webinars, podcasts, seminars and workshops, certifications and courses, even in-person meetings such as trade shows or local networking events. Experiment with different learning formats to find out what works best for you.

Want to learn more about RCI’s upcoming events and education? Click here to receive notifications about when registration opens for events and education courses, like RCI’s Chocolate Boot Camp and Annual Convention & Industry Expo.

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Tags:

Candy Making

Chocolate

Chocolate Boot Camp

Education

Enrobing

Shelf Life

Tempering

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, February 12, 2019

Updated: Monday, April 27, 2020

|

Checking your temper is an important step to ensure you aren’t surprised by unsightly bloom or dull or tacky chocolates.

Chocolates that have a dull appearance may be over tempered, while rapid bloom or a tacky, greasy surface are indicators that chocolate is under tempered. Quit guessing and rest assured your chocolate is always in good temper with these two methods for checking your temper.

The Blade Test: This method is quick, easy and budget friendly; however, the results could vary on the temperature of the room.

Simply dip a metal spatula or knife blade into the chocolate and leave a small film on the blade. At room temperature (65-68° F), well-tempered chocolate should be firm, not tacky, after just five minutes.

Tempermeter: Although more costly, this method will most accurately measure the degree of tempering, indicating the quality and quantity of stable crystals that have been formed.

Tempermeters produce a temperature-versus-time curve, resulting from uniform cooling of a chocolate sample over a specified period of time.

It may be easy to assume your chocolate is well tempered and ready to move into the assembly line, however, skipping this step could result in a costly mistake.

Choose a testing method that works best for you and put a plan in place to ensure your chocolate is being checked on a regular basis. Many of our candy maker members have a system in place to verify their chocolate’s temper every hour.

Next week: Check your chocolate knowledge and stay tuned for details on RCI’s 2019 Chocolate Boot Camp®!

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. Plus, review past blog posts for quick and actionable tips to apply to your business. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Tags:

Chocolate

Chocolate Boot Camp

Tempering

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, August 14, 2018

Updated: Monday, April 27, 2020

|

Not only do roasted nuts add satisfying crunch and crave-worthy sweet and salty flavors to chocolate confections, the pungent aroma of freshly roasted nuts, alone, can lure nearby shoppers into your candy store. This week’s brief tip, shared during RCI’s Chocolate Boot Camp®, is a must for candy makers who roast their own nuts.

REDUCE THE RISK OF BLOOM

To reduce the risk of fat bloom, due to fat migration, wait at least 48 hours to coat roasted nuts with chocolate. This practice allows the oils to reabsorb into the nuts. Keep in mind, dry roasted and whole nuts will have less free fat than those that are oil roasted.

STOP CRACKS IN THEIR TRACKS

Waiting to enrobe roasted nuts will also help lessen the chances of unwanted cracks in these chocolate-covered morsels. Quick and easy tips like these will help ensure your nutty delights look and taste as good as they smell!

Tags:

bloom

Candy Hacks

Chocolate Boot Camp

Chocolate-Covered Nuts

Cracks

Nuts

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, January 30, 2018

Updated: Monday, April 27, 2020

|

In honor of RCI’s upcoming Chocolate Boot Camp® course, taking place February 19-22 in Waterbury, Connecticut. We’re unveiling two simple, yet highly effective tools and techniques that are sure to improve your enrobed centers.

Stringing

It may surprise you to learn that stringing or marking a coated center offers more benefit than simply identifying the center. Whether you string by hand, a fork or an automatic decorating machine, those stringing marks can hide small imperfections on the surface (such as air bubbles) and give the product a more glossy appearance. The three dimensional quality of the markings create more angles for light to reflect, much like the facets of a diamond.

TRY IT: Next time you are coating centers, mark one piece and leave the next piece smooth. The chocolate temper will be the same on both, but the strung piece will have a better shine once cooled.

Detailer Rods

|

Even a small adjustment to the detailer rod can make a big

difference to your finished product. |

Detailer rods, located after each wire belt, affect the bottom and bottom edges of the centers. When used properly, the rod is close to the wire belt and slightly below the level between the wire and cooling belts. If adjusted too low, this will result in tails (pictured on the far left) or bases (center photo). When set too high, it will remove too much chocolate, leaving thin bottoms (as seen in the photo on far right. Should the detailer be set too far away from the wire belt it can also scrape bottoms and deposit lines of chocolate onto the cooling belt. Even a small adjustment to the detailer will make a big difference in your finished chocolates.

Tags:

Chocolate Boot Camp

Chocolate Production

Enrobing

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, November 28, 2017

Updated: Monday, April 27, 2020

|

The most common way to make a meltaway is to combine tempered chocolate with melted coconut oil until it is smooth. Because coconut oil is a lauric fat, it must be added at a lower temperature so not to throw the chocolate out of temper. If the chocolate becomes untempered (or was never tempered to start with) the nice, smooth texture of the meltaway will eventually be replaced with an unpleasant mouthfeel due to the formation of fat globules.

Mixing Things Up

Consider this alternative method to making stable, smooth-textured meltaways with untempered chocolate. Instead of adding fat to tempered chocolate, combine untempered chocolate and coconut oil in a mixer. Mix at a slow speed until the temperature is below 78º F and has visibly thickened. Referred to as the “mixer method” in curriculum shared at RCI’s Chocolate Boot Camp®, it achieves the same desired stability and texture the meltaway is revered for, without the hassle of keeping temper.

Newcomers and veterans alike are invited to learn techniques of chocolate making, like this, during RCI’s Chocolate Boot Camp February 19-22, 2018 in Waterbury, CT at Fascia’s Chocolates. This popular hands-on course covers topics such as:

- Tempering

- Moulding

- Enrobing

- Chocolate Artistry

- and more!

SPACE IS VERY LIMITED! This course is expected to sell out! For complete information and to register online, visit retailconfectioners.org/bootcamp.

Tags:

Candy Hacks

Candy Making

Chocolate

Chocolate Boot Camp

Coconut Oil

Meltaways

temper

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, May 2, 2017

Updated: Wednesday, April 29, 2020

|

Today is National Truffle Day! Often considered the highest expression of a quality confection and often commands the highest price when purchasing, there’s no question why these little morsels are good cause for celebration.

A decadent truffle made with high-quality ingredients is a welcome surprise to chocolate lovers around the world, however, the surprise appearance of mold could ruin your sweet reputation. Keep reading for three ways to extend the shelf life of your truffles.

Reduce Water Activity

The high moisture of cream is often the cause of microbial growth in truffles. While cream arrives pasteurized, it is usually scalded to 190°F to ensure there’s no yeast and mold.

Reducing water activity will reduce the microbial growth and can be accomplished by:

- Replacing a portion of the cream with corn syrup

- Adding invertase (an enzyme derived from yeast)

- Increasing fat percentage

- Increasing chocolate solids

Use of Preservatives (including natural preservative options)

Preservatives can also control microbial growth. Potassium sorbate is one of the most effective options, however it is not usually considered natural. Natural preservatives might include cultured dextrose. Other preservatives can include reducing the pH of the ganache or the addition of alcohol. Legal and flavor considerations, however, must be addressed before using these methods.

Reduce Storage Temperature

A rule of thumb is that reducing the temperature by 18°F (10°C) will double the shelf life. Freezing truffles can substantially increase their shelf life, however, this must be done properly. Click here to view previous blog post on freezing truffles.

A truffle’s short shelf-life is a major challenge for many confectioners. With these tips from RCI’s Chocolate Boot Camp you can effectively extend the shelf-life of your truffles and avoid any unwanted surprises.

Get solutions to your problem candies from fellow confectioners and industry suppliers at RCI's Annual Convention & Industry Expo next month! Register online now and join us in Chicagoland June 12-16, 2017!

Tags:

Candy Holidays

Candy Making

Chocolate

Chocolate Boot Camp

Chocolate Production

Problem Candy

Truffles

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, January 17, 2017

Updated: Wednesday, April 29, 2020

|

Randy Hofberger of R&D Candy Consultants, LLC, is an active member of RCI and the lead instructor for RCI’s Chocolate Boot Camp®. This week’s post is an excerpt from his article “Crunch Without the Cracks,” which offers eight tips to reduce cracking in chocolate-covered pretzels, cookies and crackers.

Texture is so very important in our foods and is a large part of the eating experience. Many of our most popular confections have a crunchy texture and using baked goods such as cookies, crackers and pretzels is one way to provide this. When coated with chocolate, however, there is a chance the finished product will crack, making it less appealing to consumers.

What cause these fissures to develop? While it may seem that there are little micro earthquakes occurring on your pretzels or gremlins attacking the chocolate-covered cookies, one of the main culprits can be moisture entering these dry baked goods and causing them to expand. To prevent moisture from coming in contact with the finished product, one of the most obvious solutions is to use packaging with a good moisture barrier. While this will solve many of the cracking problems, there are other factors that can cause cracking. Also, this will not help any of your products that are open to the atmosphere in your display cabinets.

Other suggestions to reduce cracking in chocolate covered pretzels, cookies and crackers include the following:

- Have a uniform coating. Unequal coverage will cause different contraction rates and, thus, cracking.

- Thicker coating is a stronger coating and a better moisture barrier. Coverage should be complete without pin holes, air bubbles or thin spots.

- Using a chocolate formulated to be softer will be less prone to cracking.

- Enrobed baked goods will generally have less of a heat load and will require a gentler (less) cooling. Good cooling tunnel conditions will have little or no air movement at the tunnel entrance and a temperature of approximately 65ºF. Air velocity may be gradually increased to about 700 CFM until the chocolate is set – at which time velocity may be increased to 1200 CFM. Coldest tunnel temperatures exceed the low 50sºF. Total tunnel time should be a minimum of eight minutes, but 12 minutes is better.

If your operation requires you to maintain consistent tunnel settings because of various product mixes, increasing the tunnel belt speed will give less total cooling and more line production.

- Enrober/tunnel/feeding area relative humidity should not exceed 55%.

- Pieces to be enrobed should be room temperature or warmer (up to 78ºF).

- Pretzel and cookie packages can be opened the evening prior to enrobing. This will help them equilibrate to the atmospheric conditions.

- Rough-surfaced centers reduce cracking and the loss of the chocolate shell, e.g., salted pretzels are better than unsalted pretzels.

Tags:

Candy Hacks

Candy Making

Chocolate

Chocolate Boot Camp

Chocolate Production

crack

Problem Candy

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, October 25, 2016

Updated: Wednesday, April 29, 2020

|

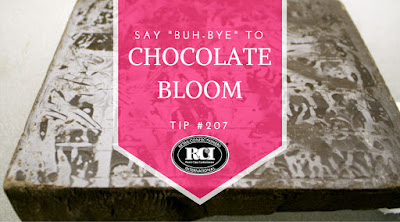

Simply put, chocolate is awesome. Consistently voted as most everyone’s favorite indulgence, it rarely fails to delight our customers. However, chocolate doesn’t always cooperate in the production of confections. Joe Sofia with Cargill Cocoa & Chocolate identifies one of the most common problems encountered with chocolate: bloom!

It can appear as spots, streaks, or a homogenous film, and can range from a dull white to a severe white discoloration, it’s bloom! The most common source is fat bloom, which is literally cocoa butter fat that has migrated to the chocolate's surface and recrystallized. While fat bloom has a negative effect on appearance, the product remains perfectly safe to eat. Pure chocolate that contains fat bloom can be remelted and retempered to reach the desired appearance. Unfortunately, finished confections that have fat bloom are more difficult to repair, since they contain fillings or inclusions and cannot be remelted.

EXCESSIVE HEAT

Fat bloom can develop for a few different reasons. Excess heat (from sunshine or warm temperatures) can cause perfectly good chocolate to bloom. The heat melts some or all of the cocoa butter, and when it recrystallizes it lacks the proper stable cocoa butter crystal nuclei and cooling for proper recrystallization. The best way to avoid fat bloom is to keep your chocolates away from heat!

POOR TEMPER

Another source of fat bloom is poorly tempered chocolate. The use of a tempermeter, or other means of optimizing your tempering step, will maximize bloom resistance in your chocolates. Both under-tempered and over-tempered chocolates will bloom faster than well-tempered ones.

INCOMPATIBLE FATS

A third source of fat bloom is the mixing of incompatible fats. If you use compound coatings, which are usually palm kernel oil based, these should not be mixed with cocoa butter based chocolate. The incompatibility of these fats can lead to inefficient crystallization and eventual fat bloom.

SUGAR BLOOM

Sugar bloom is a different type of bloom, resulting from exposure to moisture. It is formed by the dissolution and subsequent crystallization of sugar on the chocolate’s surface. It generally appears as droplets of sugar crystals on the surface of the product. If sugar bloom is moderate to severe, most likely the product will contain coarse sugar crystals and should be discarded. Sugar bloom can be avoided by keeping your refrigerated or frozen chocolates packaged and sealed until they equilibrate to ambient temperature.

Tags:

bloom

Chocolate

Chocolate Boot Camp

Chocolate Production

Education

Problem Candy

Quality Control

Permalink

| Comments (0)

|

|