After shutting down their manufacturing facility due to COVID-19, Peeps are back just in time for Easter (learn more)! This week we're sharing one way to celebrate the return of this iconic confection.

In 2019, RCI member Dolle’s Candyland, Inc. in Ocean City, Maryland shared a clever Easter idea that is too good not to share. Although many businesses are still wrestling with COVID-19 limitations, in some areas restrictions have let up substantially. While we still encourage practicing caution with regards to the virus, we are hopeful some businesses will be able to incorporate the elements of a Peep Pop event whether it be as a virtual event, an outdoor event or with participation limits.

When Dolle’s Candyland made plans to open a fourth retail store, they wanted to incorporate space where kids could enjoy hands-on candy-making experiences. For Easter 2019, Dolle’s used that space to create an event for families to bring their kids and make an “Easter Bunny Peep Pop” in their store.

After creating a public event on Facebook to spread the word, they were surprised to see people lined up out the door to make chocolate-covered Peeps. “I didn’t know that I would need stanchions [to direct the crowd],” Anna Dolle Bushnell explained, “I think we [as candy makers] take for granted what we do—people really love candy. It’s such a great thing to give them an experience like this, that really is very minimal.”

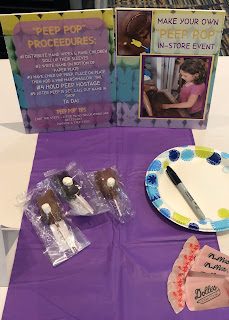

Peep Pop Procedure

Dolle's shares their "recipe" for creating a successful Easter Peep Pop event with these five easy-to-follow steps:

#1: Distribute hand wipes and have children roll up their sleeves.

Dolle's team was prepared with a large container of hand wipes, purchased from Amazon to make hand-washing a breeze while kiddos waited in line.

#2: Write child’s name on the bottom of a paper plate.

This step allows for you to hold the peep “hostage” (you’ll learn why on step #4) while it cools.

#3: Let each child dip Peep Pop in chocolate, place it on a plate and add a mini marshmallow “tail.”

This is where it’s important to keep steps to a minimum—little to no decorations are necessary. Having hosted a similar event previously, Dolle's has learned the value of keeping it simple, “if you leave sprinkles out, the kids will want to use all the sprinkles,” noted Anna. Another important tip, make sure to have a step-stool for the smaller children.

#4: Hold the Peep Hostage

This is step was emphasized by Dolle's for good reason, “Instead of walking around the store with a wet, chocolate Peep Pop, we put it through the enrober line until the Peep Pop was set up.” Adding that placing the pops in front of a fan or in the refrigerator would be suitable alternatives for anyone who doesn’t have an enrober.

The key to this step, and the overall success of this event, is while the chocolate cooled, participating families had about ten minutes to shop in their retail store.

#5: After Peep Pop is set, announce child's name in shop.

When ready, a member of the Dolle's team would read the name on the bottom of each plate before presenting the child with their finished Peep Pop. “Most of the kids would gobble it right up, but some did take them home,” Anna noted. “Some of them were beautiful, while some of them would end up having a whole pool of chocolate.”

The Conclusion

Due to the buzz created by this free, one-day event, Dolle’s Candyland increased their sales by 150% more than the day before. “People were just so thankful that we did it and some adults did it too,” added Anna. If restrictions in your area prevent your store from hosting an event, consider boxing up the ingredients and supplies for customers to make Peep Pops at home. Wishing you a “hoppy” Easter!

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Follow us on Facebook for even more sweet inspiration.