|

|

Posted By RCI,

Tuesday, February 14, 2023

Updated: Tuesday, September 5, 2023

|

P

Pate de fruit is a traditional French confection made from fruit puree, sugar and pectin. Pectin is a natural thickening agent used in jams and jellies, and gives pate de fruit its firm, jelly-like texture. In this week’s blog post, we’re sharing tips from Chef Josh Johnson with Guittard Chocolate Company on how to achieve two distinct applications for pate de fruit by using a different type of pectin.  Pictured above are two distinct applications for pate de fruit. The confection on the left used G pectin to achieve a slab pate de fruit, where NH pectin helped achieve a softer, more fluid texture that could be piped into the chocolate shell on the right. Pictured above are two distinct applications for pate de fruit. The confection on the left used G pectin to achieve a slab pate de fruit, where NH pectin helped achieve a softer, more fluid texture that could be piped into the chocolate shell on the right. G Pectin If you’re looking for a classic pate de fruit, G pectin is the way to go. Pate de fruit normally has a firm set, like a fruit jelly. Once set, it remains stable and can’t be manipulated. For an enrobed (or slab) piece, G pectin will achieve a firm consistency that cuts nicely on a guitar cutter. G pectin also offers a slower set time and a very nice fluidity when poured into a frame. This is key in being able to pour multiple frames without the product setting too quickly. G pectin is a mixture of yellow pectin, dextrose and citric acid which work together to achieve the aforementioned qualities. Be sure to not switch yellow pectin for G pectin, or the other way around, because the results will be drastically different. NH Pectin NH pectin can be used to create a softer texture, which can be stirred or blended to a smooth consistency. Once completely cooled, it can be piped perfectly into moulded chocolate shells. NH pectin is primarily used in glazes for different pastry applications, because it can be remelted and remain homogenous as a liquid glaze. NH pectin is also called “thermo-reversible pectin.” It’s important to understand the effects of different types of pectin to achieve your desired confectionery application. Click here to download Chef Josh's recipes for chocolate raspberry bon bons (pictured above) featuring pate de fruit that utilizes G pectin or NH pectin to achieve two distinctly different results. Crave more?Click here to subscribe and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices. Follow us on Facebook for even more sweet inspiration. Not a member? Click here to learn how RCI can help you build your sweet business.

Tags:

Formulations

Fruit

Pate de Fruit

Pectin

Recipe

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, February 9, 2021

Updated: Friday, August 20, 2021

|

With veganism growing in popularity, you might be considering how to appeal to this consumer group. In a past issue of RCI’s Kettle Talk

magazine, Randy Hofberger, with R&D Candy Consultants shared the following considerations for making vegan confections.

It's important to first understand and identify the challenges that may come along with adapting your recipes to meet vegan requirements and expectations. According to vegan.org, in order for a product to be approved for vegan certification:

“It must not contain meat, fish, fowl, animal by-products, eggs or egg products, milk or milk products, honey or honey bee products, insects or products from insects such as silk or dyes, or sugar filtered with bone char."

In addition to the guidelines mentioned above, the perception of what makes a product vegan must also be considered. While a refined sugar that is decolorized without bone char can be used, unrefined sugar or coconut sugar (even better) are preferred. Likewise, brown rice syrup is also preferred over corn syrup. As a general rule, the use of organic and non-GMO/bioengineered ingredients are also preferred.

After evaluating your ingredients and identifying necessary substitutions, the next step is to acquire assurances from suppliers that the ingredients you plan to use are considered vegan.

Next, understand the challenges alternative ingredients may present and how to avoid them, if possible. Although alternative sugars, like coconut sugar, can replace refined sugar/sucrose, they do present their own challenges. For example, coconut sugar has a darker color (making it difficult to get a white cream center), stronger flavor, is less sweet and more hygroscopic. Replacing corn syrup with another syrup might be less of a challenge as long as it has the same dextrose equivalent (DE) and is clarified. Unclarified syrups, such as brown rice, however, may give "off" cereal flavors to your candy.

When replacing the cream in a formulation, the first step is to look at the composition of the dairy cream—typically 36–40% fat and 55% moisture. Coconut cream has about 20% fat and 70% moisture. While you won't be able to do an exact component replacement, balancing the moisture content is probably most important. When looking to replace butter fat, consider using palm oil or natural 76º coconut oil to get the same texture and similar flavor.

When the milk protein has a function (such as stand-up quality and browning for caramels), you may be able to get desired texture using a gum. If the cooking process does not give enough caramelized color and flavor, adding a small amount of molasses may do the trick. You can also use another vegetable protein to replace the milk protein, but these often-present flavor and texture issues. Finally, if you are making aerated confections, a gum, such as agar, or a specialized soy protein are good replacements for egg albumen or gelatin.

As with any new formulation, you can expect plenty of trial and error before your vegan confections are perfected. However, your time may be rewarded with an increased customer base.

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Follow us on Facebook

for even more sweet inspiration.

Tags:

Chocolate

confections

Formulations

Vegan

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, October 1, 2019

Updated: Monday, April 27, 2020

|

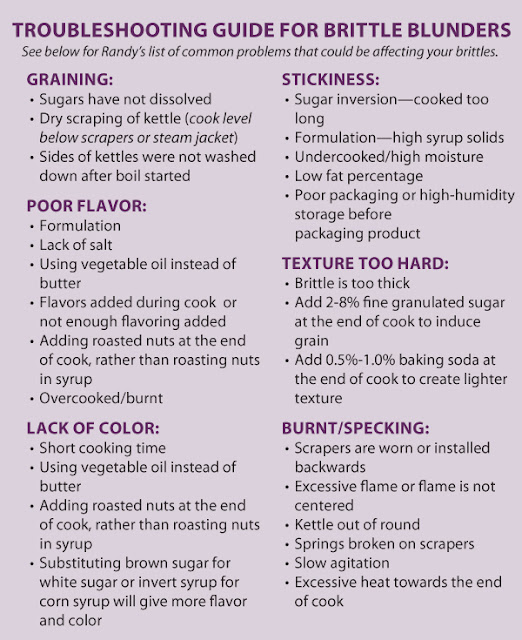

Brittles are a popular confection, with formulations that can be adjust to feature any variety of nuts, seeds and even dried fruit. In an excerpt from RCI’s Kettle Talk magazine, Randy Hofberger of R&D Candy Consultants shares how to achieve great tasting product with consistency.

This hard, glassy candy is not typically coated with chocolate, which makes it great for consumers to enjoy year around! There is no standard of identity for brittles (also known as butter crunch, nut crisps, etc.), but they generally contain sugar, corn syrup, butter, nuts, salt, flavorings and often bicarbonate of soda (baking soda).

While there are many formulas to make brittles, some typical values are:

- Sugar/corn syrup ratio of 2:1

- Milk fat: 1-15%

- Nuts: 20-30%

- Salt: 0.2-1.0%

- Emulsifiers: lecithin 0.25%, mono and diglycerides 0.5-1.5%

- Bicarbonate of soda: 0.5-1.0% (if used)

- Sufficient water to dissolve the sugars

The basic procedure to make brittles is to combine the sugar, corn syrup, emulsifier and water and bring to a boil, washing down the sides of the kettle to prevent premature graining. If your formula has a high percentage of fat/butter (such as with a butter crunch), you will want to add this at the beginning of the cook to ensure it is well incorporated. At approximately 240ºF, raw nuts are added to be roasted in the boiling syrup. Adding the nuts at this time will provide the necessary amino acids to start the Maillard reaction, which will contribute to the color and flavor of the brittle.

As the temperature approaches 280ºF, the flame is lowered if there is evidence of scorching. When the final cook temperature (usually 295–310ºF) is reached, flavoring, low levels of butter, salt and baking soda may be added. The cooked candy is taken to a warm cooling table to be stretched and cooled. Thin pieces of brittle will give a bite that is more tender. When cooled, the product must be properly packaged to maintain the crunchy texture, since brittles will absorb moisture.

Brittles can be a popular and profitable part of your candy portfolio due to their flavor, texture and resistance to heat. Like all confections, consistency is key. Consistent product requires consistent ingredients added in a consistent manner, cooked to the same temperature and for the same amount of time. Processes for cooling, transferring, packaging and storage should also be consistent.

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Tags:

Brittle

Formulations

troubleshooting

Permalink

| Comments (0)

|

|

|

Posted By RCI,

Tuesday, August 6, 2019

Updated: Monday, April 27, 2020

|

Caramels are one of the most popular candies, usually characterized by a smooth, chewy texture. In an excerpt for RCI’s Kettle Talk magazine, Randy Hofberger of R&D Candy Consultants shares how to avoid common problems like grainy texture or hardening that can develop as caramel ages.

1. CORN SYRUP SOLIDS>SUCROSE SOLIDS

When formulating your caramel recipe, the most common rule of thumb is to use more corn syrup solids than sucrose solids. This should be on a solids basis, for example, you need at least 1.25 pounds of corn syrup in your formula for every pound of sugar (sucrose).

2. DISSOLVE SUGARS

All of the sugars have to be dissolved before the completion of the cooking cycle or they will become nuclei or "seed" for graining to start. To have all of the sugar crystals dissolved, there has to be sufficient moisture in the formula—at least 20% moisture in your caramel premix to properly dissolve sugar crystals. One of the best ways to ensure a fully dissolved caramel premix is to heat it to 160˚F–180˚F while agitating and before starting the cooking process.

3. ADD SCRAP AT THE RIGHT TIME

If reworking scrap caramel, it is best to add it to the premix at the beginning of the cook cycle with sufficient moisture (remember the 20% moisture premix rule). If you have fresh scrap that is free of grain, this can be added at any time of the cooking process.

4. ADD MILK BEFORE COOK CYCLE IS COMPLETE

Different caramels procedures and recipes may require you to add milk during the cooking cycle. Make sure all of the milk is added before the end of the cooking process. Adding milk after the cook cycle may not allow the lactose in the milk to dissolve and this will promote caramel graining.

5. WASH SIDES OF KETTLE

If you have a gas-fired cooking kettle, you will want to wash down the sides of the kettle after a full rolling boil has been established. This is essential to, once again, dissolve any sugar crystals that may be on the sides on the kettle. Also make sure that the boiling level of the caramel is above the scrapers or sugar crystallization will occur.

6. AVOID EXCESSIVE AGITATION

After the cooking procedure is finished, stop the agitators in the cook kettle. Continuous agitation or excessive handling of the caramel will cause it to grain.

7. MANAGE MOISTURE

Hardened caramels are a common texture concern, which can happen when the product loses moisture. Ways to manage moisture and maintain shelf life include; adding humectants, coating the caramel in chocolate and using good, sealed barrier packaging.

8. COLDER STORAGE

As a general rule, lowering storage temperature by 18º F will double shelf life of caramel.

9. USE CHOCOLATE AS A MOISTURE BARRIER

Caramel hardening and moisture migration can occur when a drier inclusion comes in contact with a higher moisture caramel. Adding crisped rice or pretzels to the caramel will eventually cause these inclusions to get soggy and the caramel to become hard. A simple solution, if your operation permits, is to put the dry inclusion, such as crisped rice, in the chocolate that enrobes the caramel center. Chocolate acts as a moisture barrier to keep the crisped rice crunchy and the caramel soft. Putting a chocolate or specialty fat layer between caramel and a cookie base will, likewise, help keep the two components with their original texture.

Great caramels require great effort. With these tips, you can ensure your caramels stay great and your efforts aren't wasted.

Crave more? If you like what you read here, look for the "Subscribe now" box on the right to enter your email address and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's Tip of the Week blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices.

Tags:

Caramel

Formulations

Grain

Hardening

Production

Shelf Life

Permalink

| Comments (0)

|

|