Requirements for the nutrition facts label on packaged foods were updated in 2016 to help make it easier for consumers to make better informed food choices. As a producer or seller of food products, businesses of all sizes are now responsible for listing the contents of their products. Unfortunately, with an extensive list of updates to the nutrition facts label, plus a global pandemic thrown into the mix, meeting the requirements has not been an easy task for many manufacturers over the last few years.

Although the FDA announced it would work cooperatively with manufacturers, as of February 2021 (read more), it’s important your business is compliant and prepared for the FDA to begin enforcing label requirements. Keep reading for a refresher on such requirements, as well as answers to common questions and actionable steps to ensure your nutrition labels are compliant.

The what if?

If a new customer comes into your store and purchases a product without a label on it, how are they to know if it contains potential allergens? If they are allergic to an ingredient that is not listed, who’s at fault, the consumer or business? A food label with proper nutritional information serves as insurance to the business, and also notifies the consumer of a potential health risk. Without proper labeling, similar items can get shuffled on a shelf and become a guessing game of what’s inside.

Who needs it?

All too often business owners believe they are too small in production volume to require labels on their products. However, if you are selling product to a customer that they can pick up and bring to the register, the product must be labeled for the protection of the consumer and your business. Proper labeling must include a product name, ingredients/allergen statement, sell by date, and weight using a minimum of 6-point font. Well-labeled products allow the consumer to make an educated decision on whether the product will adversely affect their health by consuming it.

FDA Nutritional Label Changes in Effect

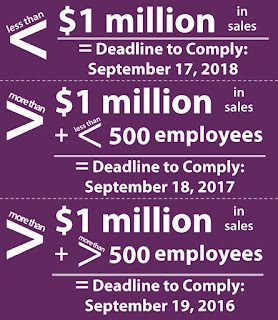

Manufacturers with $10 million or more in annual sales were required to update their labels by January 1, 2020; manufacturers with less than $10 million in annual food sales were required to update their labels by January 1, 2021.

The FDA website provides an in-depth explanation of the new nutrition label requirements, but for now, here are the important points producers need to know to ensure they are on the right path to label compliance.

Pictured above is the original nutrition facts panel on the left and the revised issue. Notable changes include larger serving sizes, added sugars and a footnote defining daily value.

Pictured above is the original nutrition facts panel on the left and the revised issue. Notable changes include larger serving sizes, added sugars and a footnote defining daily value.FDA Nutrition Label Revision Explained:

Easy Access to Information

- The well-known look of the nutrition label will remain the same, but important updates will be made to ensure consumers have all the information they need to make mindful decisions about the food they buy. These changes include increasing the type set size for data like calories per serving and serving size.

- Food producers will be responsible for declaring the actual serving amount and percent daily values like calcium, vitamin D, iron and potassium.

- The label footnote will be revised to better define what daily value means, “The % Daily Value (DV) tells you how much a nutrient in a serving of food contributes to a daily diet. 2,000 calories a day is used for general nutrition advice.”

Serving Size vs. Package Size

- Certainly, one of the most interesting changes to the FDA nutrition label updates is the serving size requirements. Until recently, serving sizes were determined based on amounts of foods and beverages that people “should” be eating. Moving forward, nutrition label updates must reflect the amount of food people are “actually” eating. Serving sizes have changed since they were suggested and published in 1993, with individuals eating larger single-serving portions.

- Many packaged foods are generally consumed in a single serving, though intended for several servings. The FDA requires packaged foods to list nutritional information for the total consumable package, apart from the recommended serving size. An example of multi-serving products generally consumed in a single serving would be “Big Grab” potato chips and packaged nuts. This new label format is termed “dual column” and aims to help consumers better understand portion sizes.

Next Steps: Reviewing & Editing Your Labels

Reviewing your product labels may seem like a daunting task depending on the number of items that you produce. It’s important to review any recipes that have changed in the past, or ingredients that have been substituted to make sure that they match on the label. Review and edit your labels in small groups to make the process of additions and revisions much more manageable. Here's some more tips to consider while updating your labels:

- Make sure each label is legible, ingredients should not be hidden or use smaller than six-point font.

- MUST HAVES: product name, net weight, sell by date, and ingredients that can be clearly read.

- Items do not have to be labeled if a product is being served to the customer from behind/over the counter.

- Software is available that will allow you to input recipes and ingredients to produce a nutrition fact panel. Look for software that is compatible with your current method of printing labels.

- Shelf talkers, or product information listed on the shelf is not a viable means of labeling products. This refers back to items being shuffled on shelves.

- Being transparent with customers on ingredients and contents is always a best practice.

Applying an accurate and up-to-date label to your products will not only help you remain in good standing with the FDA, but also help strengthen your brand and provide your customers a sense of security.

Crave more?Click here to subscribe and start receiving weekly tips, like this, delivered straight to your email inbox. RCI's blog is just one of the many resources we offer to help candy makers refine their craft and build upon their business and marketing practices. Follow us on Facebook for even more sweet inspiration.

Not a member? Click here to learn how RCI can help you build your sweet business.